In the eyewear cleaning products market, the quality of eyewear cloths has a direct impact on customer experience and brand reputation. High-quality eyeglass cloths not only clean the lenses effectively, but also extend the life of the eyeglasses. Due to its unique advantages, manufacturers are increasingly favoring the use of embossing technology in the production process.

The glasses cloth production process

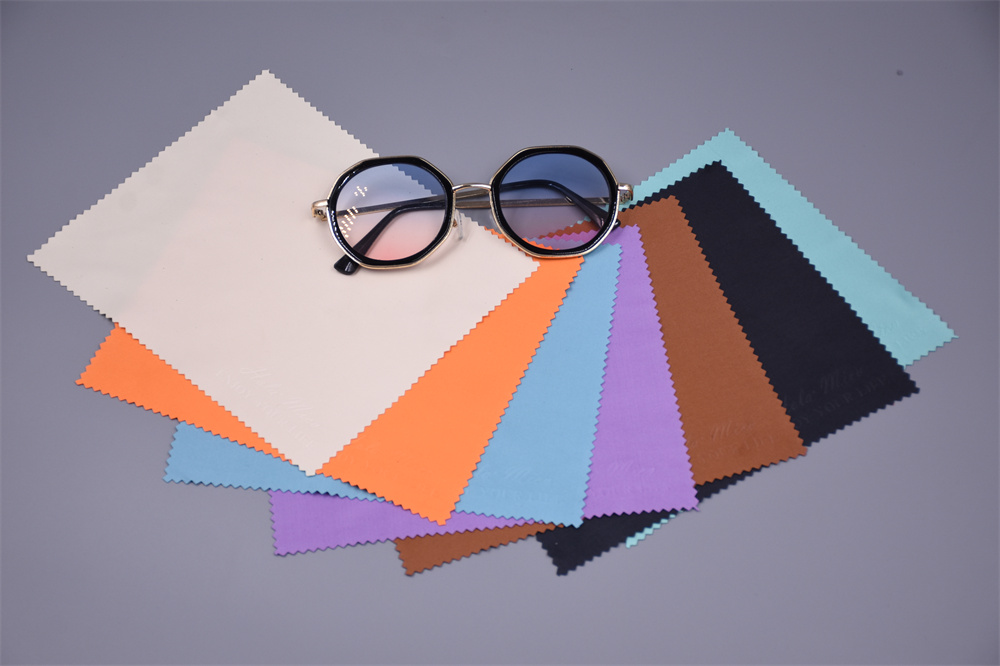

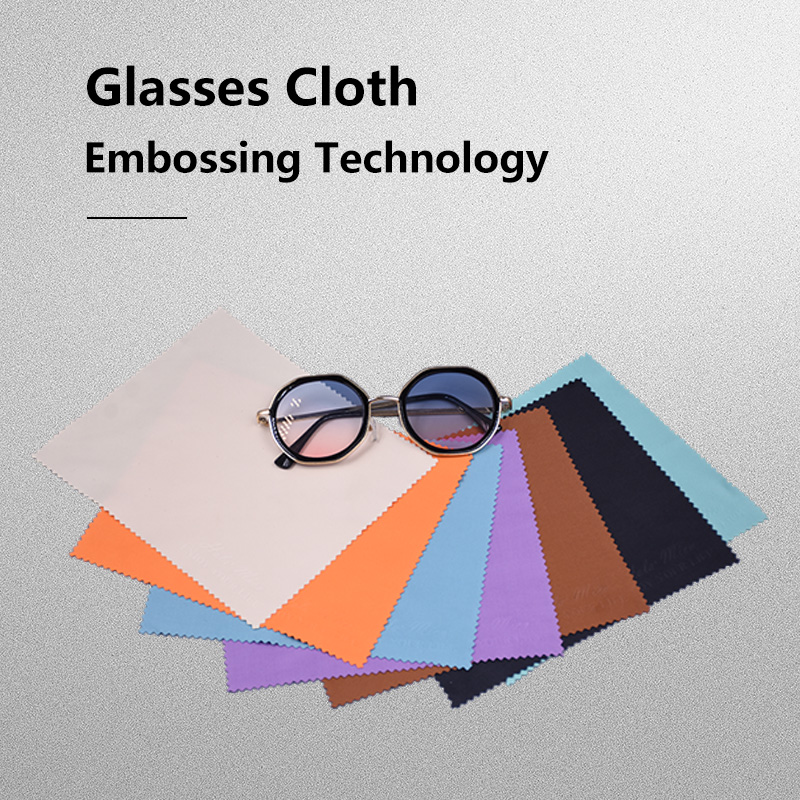

Producing eyeglass cloths involves selecting materials, cutting, dyeing, embossing, and sewing. First, manufacturers choose high-quality microfiber materials for their strong water-absorbent and stain-removing properties. They then cut the material precisely to the right size. Next, they print and dye the cloth to customize various colors and patterns according to customer needs. Finally, they use embossing technology to imprint brand logos or patterns on the surface, ensuring each piece is unique and elegant.

Application of embossing technology

Applications of embossing technology in the manufacturing of eyeglass cloths include:

- Brand Logo Embossing: This technique imprints brand logos or custom patterns clearly, enhancing the product’s aesthetics and brand recognition.

- Fine Pattern Embossing: High precision embossing allows for intricate patterns, making the cloth an artistic accessory, crucial for high-end brands.

- Functional Embossing: Specific texture or pattern can be embossed on the surface of eyeglasses cloth, which can increase the friction of the cloth and enhance the cleaning effect.

Advantages of embossing technology

Advantages of embossing technology

- High precision and clarity: Embossing can create detailed patterns and text, significantly enhancing the product’s texture and quality.

- Durability: Embossed patterns are more wear-resistant than traditional prints. They do not fade or blur, maintaining their beauty over time.

- Environmental protection: The embossing process uses fewer chemicals, reducing environmental pollution and aligning with modern eco-friendly concepts.

- Customization: Embossing process allows for flexible customization of patterns and logos, meeting diverse customer needs and increasing satisfaction.

By continuously improving the manufacturing process and adopting advanced embossing technology, we are committed to providing the highest quality products. This ensures your brand stands out in the market.

Advantages of embossing technology

Advantages of embossing technology